Description

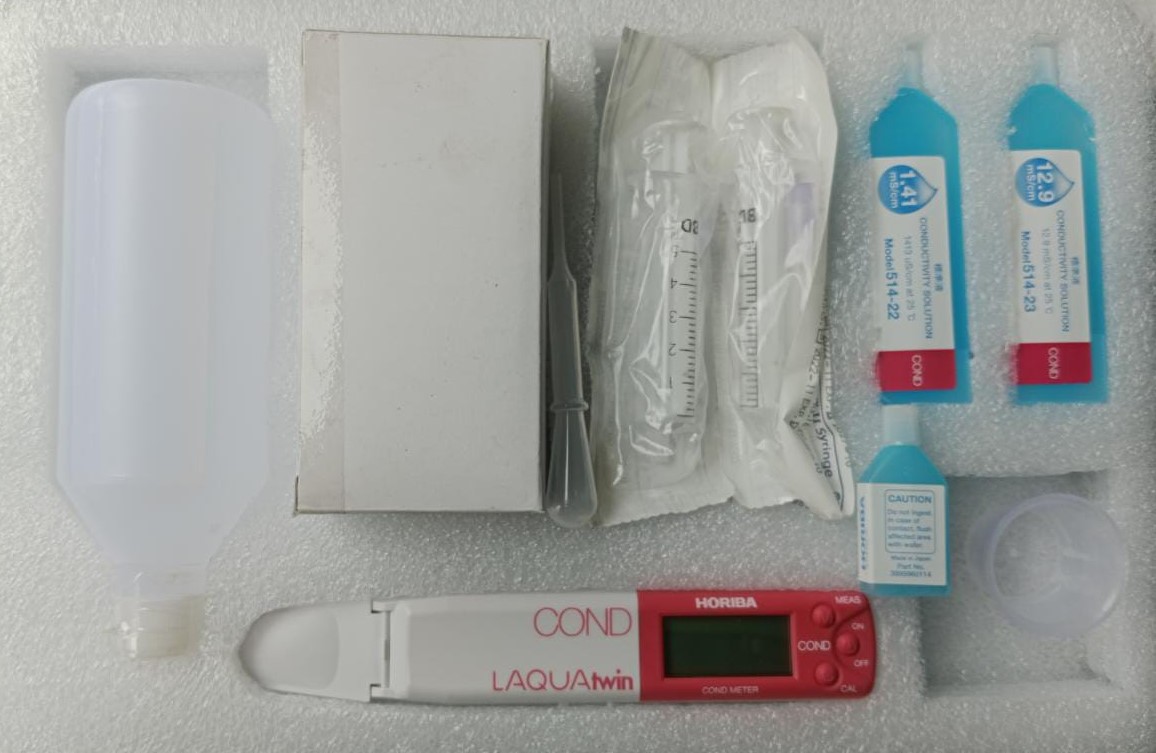

Salt contamination test kit after blasting

Bresle Test kit for measuring salt contamination on blast-cleaned steel surfaces. This kit seems to offer a comprehensive solution for assessing and quantifying salt contamination levels, which is crucial for ensuring the effectiveness and durability of protective coatings applied to steel structures.

By following the steps outlined, users can accurately measure the conductivity of the test water before and after exposing it to the surface using the Bresle Patch. The difference in conductivity readings indicates the quantity of salts present on the surface, expressed in micrograms per square centimeter (ug/cm2) or micrograms per square meter (ug/m2), depending on the multiplier used.

The inclusion of Bresle Patches Plus for testing on heavily corroded or coarse-grade blasted steel demonstrates the kit’s versatility and suitability for various surface conditions.

Having additional packs of Bresle Patches available for purchase ensures that users can continue testing as needed, making this kit a practical and cost-effective solution for industries requiring precise salt contamination measurement for surface treatment applications.

The industrial foam-filled carrying case provides convenient storage and transportation for all components of the kit, enhancing its usability in field applications.

Overall, this Bresle Test kit appears to be a valuable tool for quality control and maintenance in industries where preventing corrosion and ensuring coating adhesion are critical.

The Bresle Test Kit is a tool used in the field of corrosion protection to assess the level of soluble salts on a substrate’s surface, particularly on steel surfaces. Soluble salts can contribute to corrosion if not properly removed before applying protective coatings. The Bresle Test is a standardized method to measure the concentration of soluble salts, primarily chloride ions, on a prepared surface.

Here are key components and steps involved in the Bresle Test:

- Bresle Patch:

- The Bresle Test involves the use of a Bresle Patch, which is a small adhesive patch with a known surface area. This patch is attached to the surface under investigation.

- Extraction Solution:

- A specific volume of deionized water is added to the Bresle Patch, and the soluble salts on the surface dissolve into this water. The extraction solution is then collected for analysis.

- Conductivity Measurement:

- The concentration of soluble salts is determined by measuring the electrical conductivity of the extraction solution. The higher the conductivity, the greater the concentration of salts.

- Salt Levels and Acceptance Criteria:

- The test results are compared to established standards and acceptance criteria, which vary depending on the specific coating system being applied. Adhering to acceptable salt levels is crucial to prevent corrosion issues beneath the coating.

- Surface Preparation:

- Before conducting the Bresle Test, the surface must be properly prepared through methods such as abrasive blasting or other cleaning processes to remove contaminants and ensure accurate test results.

The Bresle Test is commonly used in industries where corrosion protection is critical, such as marine, offshore, and protective coating applications. It helps ensure that surfaces are free from harmful soluble salts before the application of coatings, thereby enhancing the longevity and effectiveness of corrosion protection measures.

Keep in mind that industry standards and procedures may evolve, so it’s essential to refer to the latest guidelines and specifications relevant to your specific application or industry.

Watch video : How to use Salt Test Kit

Reviews

There are no reviews yet.