Description

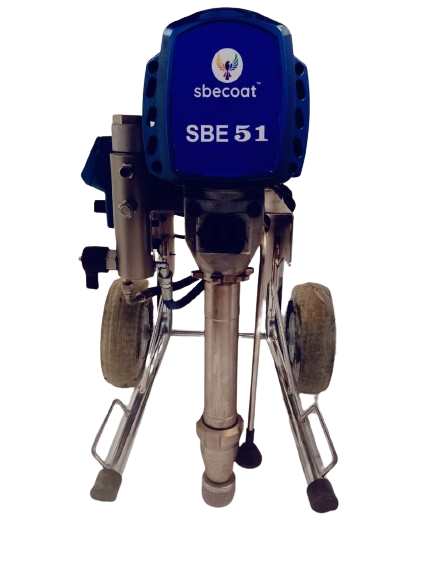

SBE 51 Electrical Airless Spray Painting Machine is heavy duty Industrial Paint Sprayer, SBE 51 having Powerful 4000 Watt Brushless Motor can pump up to 80% Volume Solid Paint, SBE 51 Airless Paint Sprayer can paint up to 200 feet, DFT in Single Coat can be 150-200 micron, Max flow rate is 7.3 liter per minute, max tip size 43 Thou, Max working pressure 3250 psi.

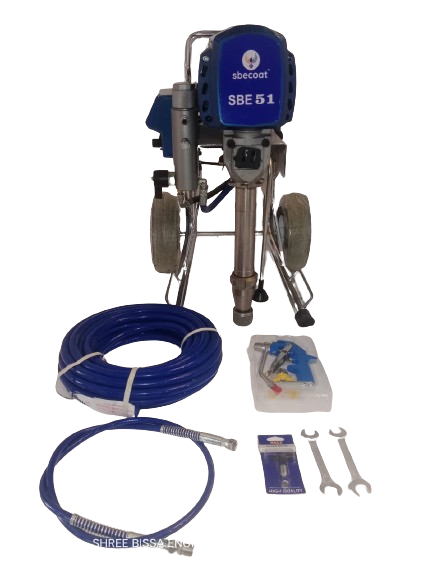

Accessories with SBE 51 ; High Pressure Paint Hose 3/8″ : 15 Miters, Paint Hose 1/4″ size 1 Meter, Airless Spray Gun 5000 PSI 01 Set with Tip and Tip Guard.

The SBE 51 Electrical Airless Spray Painting Machine stands out as a heavyweight in the realm of industrial paint sprayers. With its robust design and a formidable 4000 Watt Brushless Motor, this machine is a powerhouse capable of efficiently pumping up to 80% volume solid paint. The SBE 51 boasts an impressive reach, capable of covering up to 200 feet, and achieves a substantial Dry Film Thickness (DFT) of 150-200 microns in a single coat. Operating at a maximum flow rate of 7.3 liters per minute and a maximum working pressure of 3250 psi, it ensures a seamless and high-quality paint application process. The machine’s versatility is further enhanced by its compatibility with a maximum tip size of 43 Thou. Supplied with essential accessories, including a 15-meter High-Pressure Paint Hose (3/8″), a 1-meter Paint Hose (1/4″), and an Airless Spray Gun rated at 5000 PSI with a set of tips and tip guards, the SBE 51 is a comprehensive solution for demanding industrial painting applications.

Title: “Revolutionizing Surface Coating: The Benefits of SBE 51Electrical Airless Spray Painting Machine”

Introduction:

In the realm of surface coating applications, efficiency, precision, and cost-effectiveness are paramount. SBE 51 Electrical airless spray painting machines represent a cutting-edge solution that revolutionizes the painting process across various industries. This article delves into the advantages of SBE 51electrical airless spray painting machines and their transformative impact on surface coating tasks.

Efficiency and Speed:

SBE 51 Electrical airless spray painting machines offer unparalleled efficiency and speed compared to traditional painting methods. By atomizing paint into fine droplets and delivering it at high pressure, these machines ensure uniform coverage and rapid application, significantly reducing project completion times.

Versatility and Adaptability:

One of the key benefits of SBE 51electrical airless spray painting machines is their versatility and adaptability to diverse painting tasks. Whether it’s coating large surfaces, intricate details, or rough textures, these machines can handle a wide range of substrates with ease, making them ideal for various industries such as automotive, aerospace, construction, and manufacturing.

Uniform Coating Thickness:

Achieving uniform coating thickness is crucial for ensuring the durability and aesthetics of painted surfaces. SBE 51 Electrical airless spray painting machines excel in this aspect by delivering a consistent layer of paint, free from streaks, drips, or uneven coverage. This precision enhances the quality of the finish and minimizes material wastage.

Reduced Overspray and Waste:

Traditional painting methods often result in significant overspray and material wastage, leading to increased costs and environmental concerns. SBE 51 Electrical airless spray painting machines mitigate these issues by optimizing paint utilization and minimizing overspray, resulting in greater efficiency and sustainability.

Ease of Operation and Maintenance:

Modern SBE 51 electrical airless spray painting machines are designed for user-friendly operation and low maintenance requirements. With intuitive controls, ergonomic designs, and simplified maintenance procedures, operators can achieve optimal results with minimal training and downtime, enhancing productivity and cost-effectiveness.

Enhanced Safety Features:

Safety is a top priority in any industrial setting, and SBE 51 electrical airless spray painting machines incorporate advanced safety features to protect operators and environments. From pressure sensors and automatic shut-off mechanisms to robust shielding and ventilation systems, these machines prioritize user safety while minimizing risks associated with paint application.

Conclusion:

SBE 51 Electrical airless spray painting machines represent a paradigm shift in surface coating technology, offering unmatched efficiency, precision, and versatility across various industries. By streamlining the painting process, improving coating quality, and reducing environmental impact, these machines empower businesses to achieve superior results while maximizing productivity and cost-effectiveness. Embrace the future of surface coating with electrical airless spray painting machines and elevate your painting projects to new heights of success.

admin –

Yes